APPLICATIONS

Mission R electric motorcycle from Mission Motors featuring the high‑performance electric motor developed by Mike Kubic and Rudy Garriga

APPLICATION CASE STUDY

Motorsports

Mission Motors set multiple world records with their electric motorcycles using electric motors developed by the founders of ARD

Mission Motors was a vehicle manufacturer and technology company based in San Francisco, California, USA that developed and produced high‑performance electric motorcycles, as well as electric vehicle components and control systems.

In 2009, Mission Motors set the AMA world land speed record for electric motorcycles at the Bonneville Salt Flats in Utah, USA with their Mission One prototype electric motorcycle. The Mission One motorcycle was powered by one of the first prototype AC Induction motors developed and produced by Mike Kubic and Rudy Garriga during the early years of their company, Clean Wave Technologies.

Then in 2011, Mission Motors dominated the FIM/TTXGP world championship electric motorcycle race at the famous Laguna Seca raceway in Monterey, California, USA with their production model sport motorcycle, the Mission R. They secured the first‑place victory in the race by an almost 40 second margin and set the record for the fastest electric vehicle of any type ever at the raceway with a lap time of 1:31. This lap time approaches the speed of top MotoGP combustion engine powered Grand Prix racing motorcycles and is a record that still stands today.

The Mission R electric motorcycle featured the production version of one of several models of high‑performance AC Induction motors that Mike Kubic and Rudy Garriga developed at Clean Wave Technologies. Mike and Rudy worked with the team at Mission Motors to integrate the Clean Wave PowerFlow™ M10A2 motor and patented cooling system with a single-speed gear reduction into an integrated drive assembly. The PowerFlow™ M10A2 motor can produce over 250 kW (335 HP) in a package weighing only 34 kg (75 lb), providing unprecedented power density and performance for any type of vehicle application.

APPLICATION CASE STUDY

Passenger Vehicles

The iconic Tommykaira ZZ electric roadster from GLM is powered by an electric drive system developed by the founders of ARD

GLM is a vehicle manufacturer and engineering company based in Kyoto, Japan that develops and produces high-performance electric passenger cars, as well as integrated electric vehicle platforms.

In 2013, GLM introduced their flagship vehicle, the Tommykaira ZZ, an electric powered sports car with performance that rivals the original Tesla Roadster from Tesla Motors.

The Tommykaira ZZ features the PowerFlow™ M20A2-1X1 electric drive system from Clean Wave Technologies. Mike Kubic and Rudy Garriga led the development and production of the M20A2-1X1 system during their time at Clean Wave.

Mike and Rudy worked with GLM to customize the shaft, spline, and mounting interface of the standard M20A2 motor, as well as the high-power electric cable interfaces, to seamlessly integrate the electric motor with an off-the-shelf single-speed gear reduction and differential for a rear-motor, rear-wheel drive layout in the vehicle.

The M20A2-1X1 system provides over 225 kW (300 HP) in the Tommykaira ZZ, propelling the roadster from 0-100 kph (0-60 mph) in under 3.8 seconds.

Tommykaira ZZ roadster from GLM powered by a 225 kW (300 HP) electric drive system developed by the founders of ARD

The power‑dense electric drive system developed by Mike Kubic and Rudy Garriga enables EVAOS to integrate the electric motor in‑line with the drive shaft of Ford F‑150 trucks equipped with their Multi-Mode Hybrid systems

APPLICATION CASE STUDY

Commercial Vehicles

High-power, compact electric drive systems developed by the founders of ARD are a key enabler to the Multi-Mode Hybrid systems from EVAOS

EVAOS is a manufacturer and integrator of aftermarket hybrid electric systems for commercial trucks based in Santa Clara, California, USA. Their add-on Multi-Mode Hybrid systems allow conventional combustion engine powered trucks to be upgraded into plug-in hybrid electric vehicles.

EVAOS-equipped trucks keep their original gas or diesel engine and transmission, providing for ease of hybrid system installation, as well as enabling three different driving modes: all-electric mode for maximum fuel savings, hybrid mode for longer trips or extra towing power, and conventional mode for extended range. EVAOS systems can also provide exportable power for external electrical equipment in locations where the electrical grid is unavailable.

The EVAOS Multi-Mode Hybrid systems utilize the PowerFlow™ M20A3-1X1 electric drive systems from Clean Wave Technologies, for which Mike Kubic and Rudy Garriga led the development and production during their time at Clean Wave. Mike and Rudy worked with EVOAS to develop a custom dual-shaft configuration of the M20A3 motor, enabling the electric motor to be integrated directly in-line with the existing drive shaft of the vehicle. This unique configuration thus allows the OEM combustion engine, transmission, and differential to stay in their original factory layout, with only minor modifications to the OEM drive shaft needed to accommodate the addition of the electric motor.

The extraordinarily compact size, unique form factor, and exceptional power density of the M20A3 motor is a key enabler to the Multi-Mode Hybrid systems from EVAOS, adding up to 165 kW (220 HP) of power and 430 Nm (315 ft-lbs) of torque to the existing OEM powertrain.

APPLICATION CASE STUDY

High-Performance

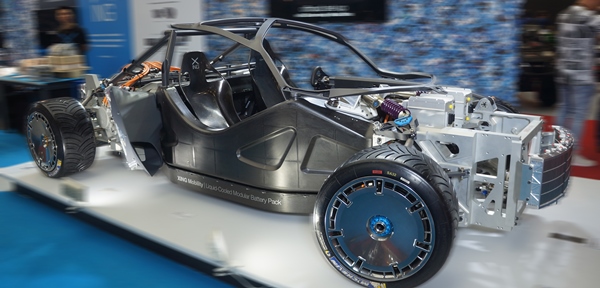

Xing Mobility utilizes electric drive systems developed by the founders of ARD to realize their advanced electric vehicle powertrains

Xing Mobility is a vehicle engineering and manufacturing company based in Taipei, Taiwan that innovates advanced energy storage and electric powertrain solutions using extremely high‑performance vehicles and racing applications as their development and testing platforms. Their mission is to enable any type of vehicle maker to switch from combustion engines to electric propulsion by utilizing their tightly integrated electric powertrain systems.

One of XING Mobility’s development vehicles is the Miss R, an electric‑powered supercar capable of producing 1 MegaWatt (1,340 HP) of power! The car features a total of four PowerFlow™ M20A2‑1X1 electric drive systems from Clean Wave Technologies, with each of the electric motors independently driving each of four wheels of the vehicle. The founders of ARD, Mike Kubic and Rudy Garriga, led the development and production of the M20A2‑1X1 drive systems and collaborated with XING Mobility on the vehicle integration during their time at Clean Wave.

Another vehicle that XING Mobility developed to demonstrate their products and technology is a 1969 Chevrolet Camaro converted to electric drive utilizing a 240 kW (320 HP) electric drive system also developed by the founders of ARD during their time at Clean Wave Technologies. For this electrified version of the classic American muscle car, the electric motor is adapted to connect directly to the original transmission of the vehicle. XING Mobility developed the system as a complete aftermarket conversion kit to provide an easy‑to‑install, high‑performance, fully‑integrated electric powertrain solution. The car and integrated conversion kit were featured at the 2019 SEMA show in Las Vegas, Nevada, USA.

Chassis of the Miss R electric supercar from XING Mobility featuring four electric drive systems developed by the founders ARD capable of producing a total of 1 MegaWatt (1,340 HP) of power!