SERVICES

ARD is a full‑service engineering & manufacturing company specializing in the design, production, testing, and integration of high‑performance electric drive systems & components

Our experience, knowledge, and commitment to excellence enables ARD to provide the highest quality and most advanced products & design solutions in the world

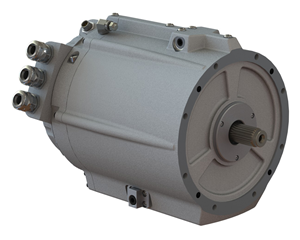

Electric Machines

ARD designs and produces custom AC Induction and Synchronous Reluctance machines to meet exact and demanding specifications

With our technology, experienced design approaches, and proven processes, ARD is able to provide electric machines with industry-leading power density and efficiency, the highest level of quality and reliability, as well as the most cost-effective and manufacturable designs

- Motoring & generating operation

- Performance to meet any required torque & power profiles

- Size, weight, and physical configuration optimized to fit customer needs

- High-speed operation up to 20,000+ RPM

- Specialized steel lamination configurations & material selection

- Aluminum or copper rotor cage material for AC Induction machines

- Customizable stator winding configurations

- Shafts, splines, bearings, and seals designed for high-speed, high-load operation, providing for high reliability with 10,000+ hours operating life

- Custom output shaft configurations, including single & dual shaft layouts, internal or external splines, standard & custom spline profiles, as well as a variety of other shaft connection interfaces

- Internal oil cooling, external water cooling, or combination of both

- IP67 level of ingress protection or higher as required

- Mechanical & electrical interfaces tailored to customer requirements

- Products can be designed to pass highest levels of ISO 16750 / 19453 / 20653 environmental testing standards

Power Electronic Controllers

ARD designs and produces custom power electronic controllers that are perfectly matched to our custom machine designs to achieve the highest performance possible

We utilize leading-edge technologies and leverage our significant experience in machine control theory to provide power electronic units with industry-leading power density and efficiency, the highest level of quality and reliability, as well as the most cost-effective and manufacturable designs

- Custom power inverter topologies & system architectures

- Silicon IGBT & Silicon Carbide MOSFET power devices

- High voltage operation as required up to 1000+ VDC input

- Microprocessor & FPGA control architectures

- Proprietary advanced embedded torque control firmware that produces commanded torque from matched AC Induction or Synchronous Reluctance machines to within +/-2% over full range of torque-speed profile

- Customizable control software & user interfaces

- Communication interfaces compliant with SAE J1939, including CAN 2.0A and 2.0B protocols

- Size, weight, and physical configuration optimized to fit customer needs

- Liquid or air cooled designs

- IP67 level of ingress protection or higher as required

- Mechanical & electrical interfaces tailored to customer requirements

- Members of the ARD team have been certified as ISO 26262 Functional Safety Engineers and can support development to ASIL D classification requirements

- Products can be designed to pass highest levels of ISO 16750 / 19453 / 20653 environmental and ISO 11452 / 7637 EMC testing standards

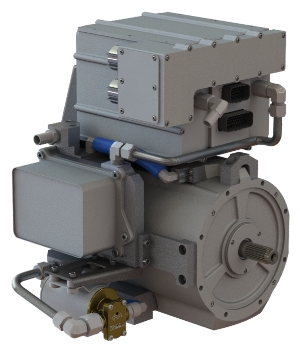

Electric Drive Systems

ARD designs and produces complete electric drive systems that include matched electric machines and power electronic controllers, as well as comprising other matched ancillary components

- Electric machines & power electronic controllers may be separate units or combined together into single integrated systems

- May be integrated with off-the-shelf or custom transmissions & gear boxes

- May include integrated cooling systems, including pumps, filters, fans, and radiators / heat exchangers

- May include LED indicator lights and/or digital readout displays

- May include other ancillary components, such as contactors, relays, resistors, interlocks, switches, and other power distribution devices

- Seamless power, cooling, and control interfaces between all integrated system components

- Size, weight, and physical configuration optimized to fit customer needs

- Mechanical & electrical interfaces tailored to customer requirements

Manufacturing

As experts in production operations and strategies, ARD offers a variety of options for manufacturing our products to best fit individual customer needs

- Low volume & one-off production performed in-house by ARD

- Higher volume production handled with out-sourced CMO partners

- ARD works directly with CMO partners for seamless customer experience

- Designs & process instructions can also be transferred to OEM customers for management of mass production operations

- Regardless of manufacturing solution, ARD can provide sustaining engineering support throughout the entire product lifecycle

ARD also has extensive expertise in materials and manufacturing processes, including advanced fabrication methods and quality management systems for both low and high volume production

- Optimized material & process selection to best fit customer requirements

- Precision machining techniques for maintaining proper tolerances

- Stamping, bending, forging and other metal forming processes, including automated progressive die operations

- Gravity & pressure die castings, plaster mold & investment castings, injection moldings, and extrusions

- Welding, brazing, soldering, hardening, heat treating and other complex metallurgical processes

- Specification of material properties, fabrication surface finishes, and material coatings, such as plating, anodizing, chromate conversion (Alodine), and powder coating

- Dimensional quality control with Coordinate Measuring Machine (CMM) inspection and statistical process control tools

- Development of automated assembly and testing processes for high-quality, repeatable, and cost-effective volume production

- Design, development, production, installation, and servicing of products per IATF 16949:2016 Quality Management System standard

Testing

ARD leverages years of hands-on experience and maintains close relationships with outside partners for comprehensive and verifiable testing of our products for validation, qualification, compliance, and certification

- High-speed active dynamometer testing in both motoring and generating modes up to 400 Nm continuous torque, 700 Nm peak torque, 15000 RPM, and 1000 VDC input voltage

- Product validation testing to ISO 16750 / 19453 / 20653 environmental standards, including electrical loads, mechanical shock & vibration, high & low temperature storage & operation, temperature steps & cycling, salt fog, humidity, ingress protection, and chemical resistance

- Product validation testing to ISO 11452 / 7637 EMC standards, including radiated, conducted, and coupled immunity

Integration

ARD has a wealth of real-world experience & know-how with integrating electric drive technologies at both the component & system levels

- High-power electrical interconnections, high-voltage AC & DC cabling, and low-voltage signal wire harnesses

- Mechanical mounting and shock & vibration control

- Interconnection of rotating shafts with custom couplings & spline interfaces

- Laser alignment & precision balancing of high-speed rotating shafts, gears, couplings, machines, and complete dynamometer test systems

- Integration of ancillary components, such as pre-charge circuits, safety interlocks, user interfaces, and cooling systems

- Extensive practical experience in handling the challenges of grounding, shielding, insulation, and EMI suppression associated with the integration of high-power AC electromechanical systems

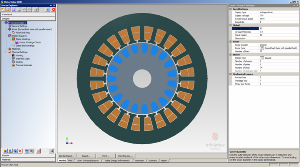

CAD & Simulation

ARD utilizes proprietary FEA models that have been calibrated to empirical test results for accurate simulation of electric machines, thermal management systems, and structural integrity

- AC Induction machine analysis & design with Mentor® MotorSolve IM

- Synchronous Reluctance machine analysis & design with Mentor® MotorSolve BLDC

- Thermal analysis & design with Mentor® FloTHERM and MotorSolve Thermal

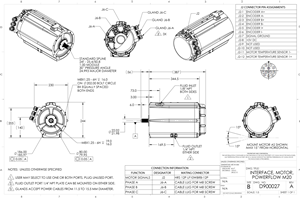

- Mechanical 3D CAD and structural analysis & design with SolidWorks®

- Taguchi robust design methods employed for sensitivity analysis of simulation variables, including design of experiments for optimization of system parameters

Engineering & Design

ARD leverages extensive experience in developing new technology, designing products, and solving engineering challenges across diverse industries to offer unique and practical state-of-the-art solutions to a variety of engineering and design projects

- Overall technical expertise specializing in the design & manufacturing of complex high-power electromechanical systems and high-speed rotating machinery

- Design, installation, and calibration of precision high-speed dynamometer test stands with direct-drive active loading operation for both R&D and production line testing applications

- Development & installation of industrial equipment, operating mechanisms, and other devices for manufacturing, testing, and process control

- Electronics hardware packaging, especially high-power, high voltage systems, such as AC inverters, DC-DC converters, and other types of power supplies, including EMC & thermal management for the complete system

- Heat sink design for liquid or air cooled systems, optimizing the balance of high thermal performance with size, weight, and cost-effective fabrication & assembly processes

- Design for manufacturability, especially to support automated assembly and testing for high-quality and cost-effective volume production

- Product cost analysis and optimization with proficiency in developing and implementing systematic cost reduction strategies involving comprehensive engineering, supply chain, and manufacturing initiatives

- Complete product development from initial concept through end-of-life, including product definition and specifications, detailed design and fabrication drawings, bill of materials (BOM) and procurement strategy, prototyping and design verification testing (DVT), assembly and test documentation, release to manufacturing, inventory strategy and supply chain management, production ramp, and sustaining engineering

- Geometric Dimensioning & Tolerancing, along with critical dimensioning of fabricated parts and statistical tolerance analysis for dimensional stackups in complex assemblies, including 2D Root Sum Squared (RSS) method and 3D Monte Carlo simulations

- Document control process and product data structure, including product data management (PDM) & product lifecycle management (PLM) databases